The Role Of Robotics In Modern Manufacturing

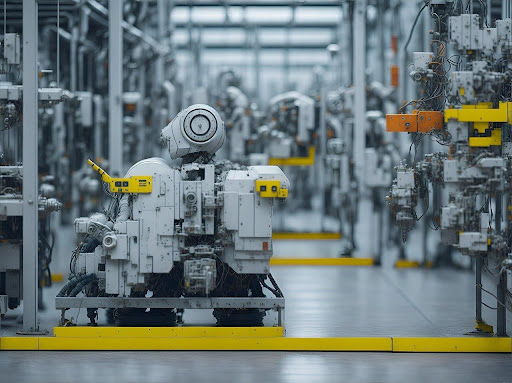

Today, in the world of manufacturing, robotics play a huge role in making cars, electronics, and many other products. This journey began in the 1960s with the very first programmable robot, Unimate. It started automating tasks that were previously done by hand, thereby increasing production speed.

Author:Finn WildeReviewer:Michael RachalJul 21, 202436 Shares36.4K Views

Today, in the world of manufacturing, robotics play a huge role in making cars, electronics, and many other products. This journey began in the 1960s with the very first programmable robot, Unimate. It started automating tasks that were previously done by hand, thereby increasing production speed.

Fast forward to the 1980s and 1990s; the sophistication in robotics development resulted in complex tasks initially performed by technically advanced robots. It became well manifested in the automotive, food processing, and electronic industries. In the 21st century, Industry 4.0 ushered in a new era of robotics. Advanced technologies, involving Artificial Intelligence and the Internet of Things, have made it possible for robots to get smarter and more autonomous.

These innovations have led to products like disturbance switches and vibration switches from leading motion sensor switch manufacturers, enhancing efficiency, accuracy, and flexibility across various industries. So, how are robots reshaping manufacturing, from the assembly line to high-tech industries?

9 Roles Of Robotics In Modern Manufacturing

Robotics paves the way for innovation and efficiency into many industries. Here are nine important roles that robots play in modern manufacturing:

1. Increased Productivity And Efficiency

Inclusion of robots in the manufacturing processes to a great extent increases productivity and efficiency. Robots do repetitive jobs more efficiently and accurately, hence saving time and reducing production errors. Unlike human beings, robots never get tired or require breaks. They’re good at handling monotonous, tiring, and physically demanding productions that require high precision and speed.

Whether it’s assembling products, packaging goods, or moving materials, these robots can handle tasks tirelessly without errors. In this respect, such processes increase productivity and efficiency in general for the manufacturer when automated.

2. Enhanced Quality And Consistency

It’s in the nature of robots to repeat processes consistently, hence improving quality and reliability in products. They could also do very subtle repetitions of similar activities to ensure that every product meets the required specification. This reduces defects and waste, increases customer satisfaction, and enhances manufacturers' reputation.

3. Precision In Manufacturing

Accurate manufacturing requires a high level of precision, particularly for complex assemblies and sensitive parts. Robots are fitted with advanced sensors, computer vision, and AI that aid in realizing very accurate results. They can work with processes whose accuracy goes as low as microns, ensuring the highest possible standard of quality is maintained.

Additionally, robots can perform real-time quality checks, enabling instant identification and alleviating passage of faulty products to the market.

4. Workplace Safety

Robotics has greatly improved the working conditions in a manufacturing setup. Non-friendly tasks are performed by robots, from heavy lifting to welding and exposure to toxins, thus reducing the risks posed to human life.

Manufacturers can create safer environments with fewer accidents by assigning tasks from humans to robots.

5. Flexibility And Adaptability

Flexibility in modern manufacturing is achieved by accounting for the changes in market needs and consumer taste. Robots can easily be reprogrammed to various tasks; therefore, in a production lineup, any change in product manufacture can easily be made.

This flexibility is vital in industries where frequent product changes or short production cycles have been happening.

6. Cost Savings

Although initially investment-intensive, robots offer numerous long-term advantages. Robots increase productivity and quality, reducing labor, material, and waste costs.

Automation of processes speeds up production and time-to-market, enhancing revenue potential for companies.

7. Data-driven Decision Making

Modern robots, equipped with advanced sensors and data collection tools, can measure everything from the performance of a machine to product quality, energy consumption, and much more. Manufacturers work with this data, improving how they work by making better decisions and optimizing processes.

8. Collaborative Robotics (Cobots)

Collaborative robots, or cobots, are a new trend in manufacturing. Unlike traditional robots, cobots work alongside humans. They handle repetitive tasks, while humans do complex jobs. This teamwork boosts efficiency, makes work safer, and makes it more satisfying.

9. Addressing Labor Shortages

Manufacturing needs more skilled workers in many places. Robots can help by doing tasks that need skills that are hard to find. This lets humans focus on important jobs like design, maintenance, and quality control.

Finn Wilde

Author

For Finn Wilde, the wilderness is more than just a destination - it’s a way of life. Over the past decade, he has led multiple expeditions in some of the world’s most remote regions, from the icy fjords of Greenland to the rugged trails of Patagonia.

Finn emphasizes sustainability in all of his adventures, helping participants connect with nature while promoting responsible exploration. His expeditions inspire individuals to explore the great outdoors while fostering a deep respect for the environment.

Michael Rachal

Reviewer

Michael Rachal believes that luxury lies in the details. With over 20 years of experience in the luxury travel industry, he has crafted hundreds of bespoke itineraries for clients seeking personalized, unforgettable experiences.

Whether guiding clients through private cultural tours or curating culinary journeys with world-renowned chefs, Michael ensures that each trip is tailored to perfection.

His ability to anticipate needs and exceed expectations has earned him a reputation as a leading expert in luxury travel.

Latest Articles

Popular Articles